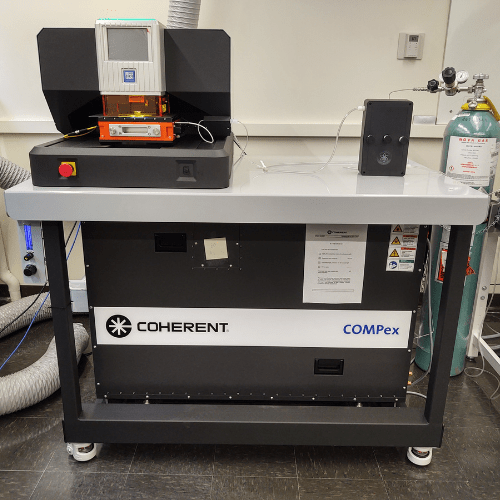

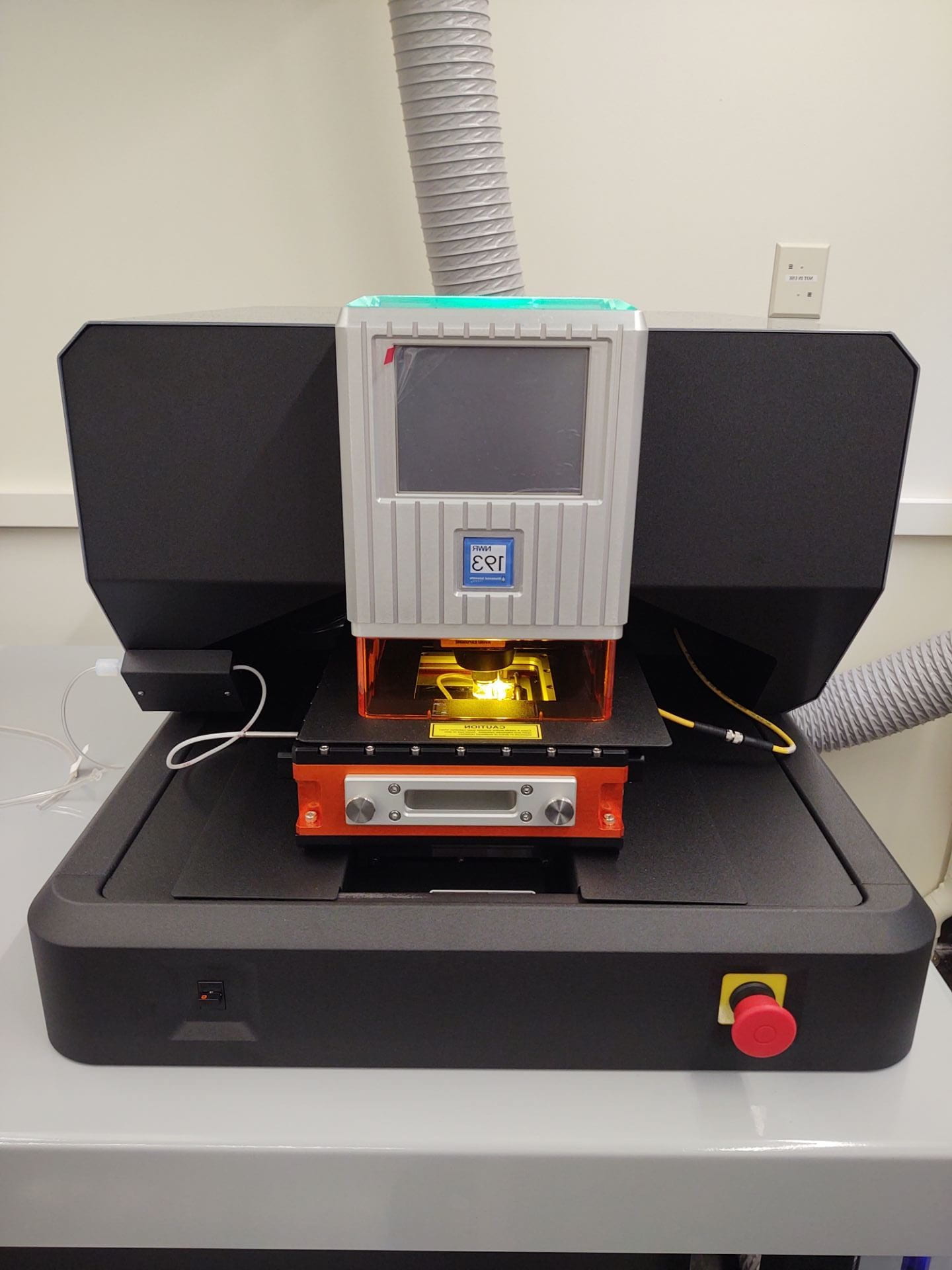

The CMaS facility at Cornell University houses an ESI NWR193UC excimer laser and an Agilent 8900 ICP-QQQ (ICP-MS/MS).

The NWR193HE laser is capable of precision spot analyses ranging from 1-150 µm with variable and customizable energy settings, including a high fluence mode capable of up to >50 J/cm^2, and XYR settings for rectangular analysis. The Agilent 8900 triple quadrupole provides high accuracy data and mass interference offset with use of additional gases such as H, He, O, and NH3. The mass interference offset offers improved resolution of analytes with high backgrounds, such as P, and analytes with isobaric mass overlaps, like 204Hg and 204Pb, compared to traditional single quadrupole techniques. See the “Applications” tab for more details.

Trace element analysis, isotope ratios, and trace element mapping are the most routine measurements performed in the Cornell Mass Spectrometry Facility. The Agilent 8900 can be used to analyze solid samples from a variety of disciplines including geology, materials science, biology, and more.

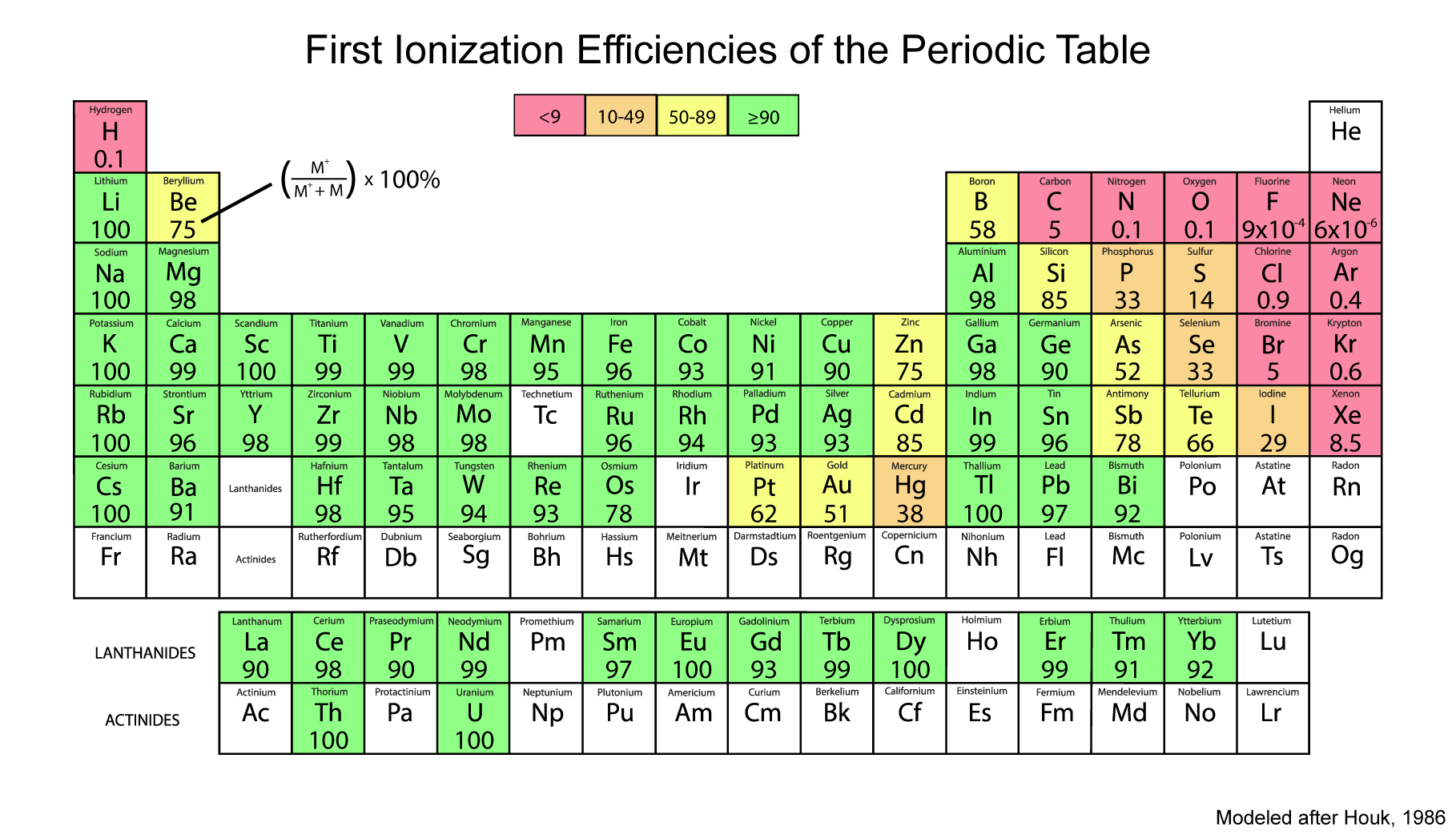

The periodic table below shows which elements are most reliably detected by ICP-MS applications. Many elements are efficiently ionized to a +1 state in the Ar plasma of the ICP-MS, allowing the electromagnetic detector to discern and count ions based solely on their unique elemental mass to charge ratio. Some elements with lower ionization efficiencies (i.e., <50%) can still be quantifiably detected in the ICP-MS, but the lower the ionization efficiency the more difficult detection becomes. Elements with both low ionization efficiencies and high backgrounds (e.g., N) may not be possible to measure on the Agilent 8900.

Quantitative mass spectrometry techniques require an internal standard reference material with known composition is analyzed concurrently with ‘unknown’ samples. The best internal standards are composed of similar matrix material as the unknown samples. Before scheduling, please discuss the purpose of the analysis, analytes of interest, and internal standard requirements with the operator.

Testing updates